Fixture feet from norelem

Fixture feet are standard parts that help to ensure the exact positioning of parts or workpieces. A standard part is a standardised component. It is produced in industrial manufacturing according to standardised specifications and has the advantage that it is widely used. Furthermore, the standardisation of the part leads to easy replaceability.

The positioning feet are standardised according to international or industry-specific standards such as DIN (German industry standard) or ISO (Internationale Organization for Standardization). The standards often define parameters such as size, material, tolerances and other technical specifications.

What are positioning feet?

Application areas and functions of the fixture feet

Swivel feet in the norelem range

Advantages of fixture feet from norelem

What are positioning feet?

The positioning feet can also be referred to as fixture feet or swivel feet. These are parts that are used to align, position or stabilise tools or other components. This can be the case in various industrial applications. The positioning elements are often used as supports, stops or even thrust pads.

Application areas and functions of the fixture feet

Fixture feet are used in various industries and applications, particularly in machine construction, production engineering, tool mechanics and other technical areas. The purpose of standard parts is to ensure accurate positioning of parts or workpieces. Here are some basic functions of the swivel feet:

- They offer stable and solid supportto ensure that the workpiece remains in the desired position during the machining process or in the fixture.

- To ensure precise processing, positioning feet can be used to position several parts or workpieces in the same way.

- They are used to support, hold or carry workpieces, especially when it is important that certain surfaces or features of the workpiece are accessible.

- Definition and limitation of the workpiece position

- They can be used to ensure that parts are placed consistently or to define specific processing areas.

- They can be used as holders or fastening elements to ensure that the workpiece does not slip during processing.

Swivel feet in the norelem range

There are seven standard parts in the positioning feet product family. They differ in terms of material, mounting and contact faces, the diameter of the support and the thread size.

Feet with threaded pin DIN 6320

The feet with threaded pin are available in two forms.

- Form A – with smooth contact face

- Form B – with carbide tips

The feet are manufactured acc. to DIN 6320 and are frequently used in fixture construction. They are used when neither a self-aligning pad nor axial adjustment is required.

The DIN 6320 feet are made of high-carbon steel 1.1172 in accordance with the official standard sheet.

Positioning feet

Positioning feet are strongly represented in the norelem range. A distinction is made between free-cutting steel positioning feet and positioning feet with high-carbon steel body.

The free-cutting steel positioning feet are available in eight forms.

- Form A - External thread and flat face

- Form B - External thread and spherical face

- Form C - External thread and serrated face

- Form D - Internal thread and flat face

- Form E - Internal thread and spherical face

- Form F - Internal thread and serrated face

- Form K - External thread and carbide serrated face

- Form L - External thread and POM insert

You can find an illustrative sketch of the forms here.

The positioning feet with the high-carbon steel body have a case-hardened contact face. They are used to support machined and raw tools.

The standard parts are available in four different forms:

- Form A - Flat face hardened

- Form B - Flat face ground and hardened

- Form C- Hardened spherical face

- Form D - Tempered serrated face

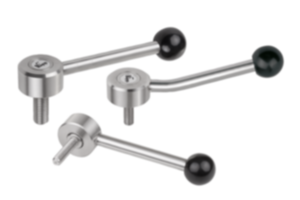

fixture feet with external thread

| The fixture feet with external thread are suitable for thread sizes M10 and M12. They are made of high-carbon steel 1.1181 and are available in various heights. The height ranges from 50 mm to 75 mm, 100 mm and 125 mm. |

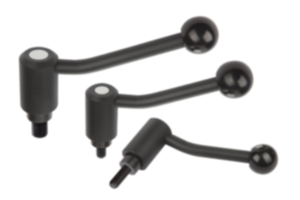

Fixture feetwith internal thread

The body of the Fixture feetwith internal thread is black oxidised and made of high-carbon steel. The contact faces are case hardened. The fixture feet are available in four forms.

- Form A - Flat face hardened

- Form B - Flat face ground and hardened

- Form C- Hardened spherical face

- Form D - Tempered serrated face

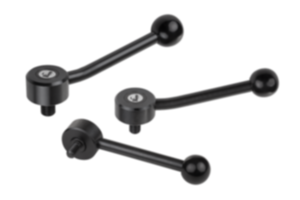

Fixture feet

| The Fixture feet in the norelem range are available with a support diameter of 16 mm, 20 mm, 25 mm, 32 mm and 36 mm. They are made of steel, and are hardened and black oxidised. |

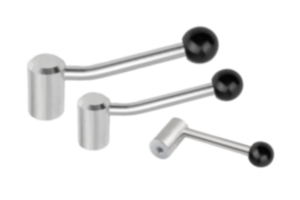

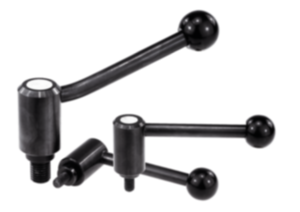

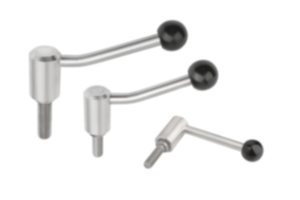

Swivel feet

The ball element of the Swivel feet is case hardened and made of free-cutting steel. The pressure foot, on the other hand, is made of ETG 100 special steel. The diameters of the swivel feet range from 13 mm to 32 mm.

Advantages of fixture feet from norelem

The positioning elements from norelem offer a number of advantages that are appreciated in various industrial applications. Thanks to their high-quality production and versatility, the standardised parts help to ensure precise positioning, secure fixating and optimum alignment of components.

norelem offers an extensive range of positioning elements, including positioning feet, swivel feet, fixture feet and many more. This variety allows you to select exactly the elements that best meet your specific requirements. Compliance with the international DIN standard emphasises the quality and conformity of the parts with global standards.

Do you have any questions or special requests regarding our products?