Spur gears, racks

Spur gears ensure a positive and non-slip transmission of forces with alternating directions of rotation, such as for raising and lowering machine elements or loads. The combination of gear rack and spur gear converts rotary motion into linear motion or linear motion into rotary motion and is widely used in applications in mechanical engineering and plant construction.

Spur gears

Spur gears from norelem ensure a positive and non-slip transmission of forces, also by alternating rotation directions such as found by raising and lowering heavy loads.

Uses include transposing rotary movement to linear movement and diverse drive applications. Spur gears add another chapter to the parts range together with the toothed belts and chains already on offer.

Diameters are from 14 - 387 mm. The tooth width is 15 - 30 mm. If required, the gear wheels can be made with a hub to ease mounting on the machine or workpiece.

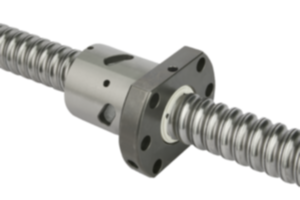

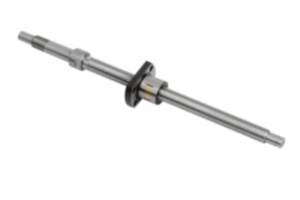

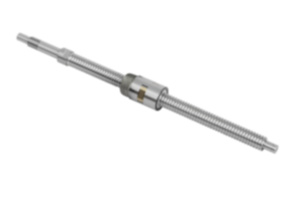

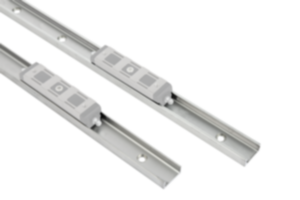

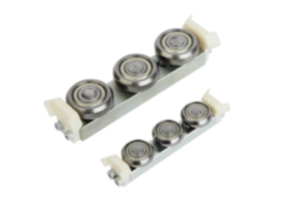

Rack and pinion

A rack and pinion is especially suited to manufacturing automation in machine and plant construction. A gear rack ensures high repeat precision as precise positioning is no problem within the driven range.

With a gear rack from norelem, even the transmission of high torques does not present any practical problems. A gear rack defies high traversing speeds as well as frequent changes in direction by differing loads. This is why rack and pinions are optimum for continuous assemblies as by robotics.

Bevel gears

Bevel gears transmit angular torque in machine and plant construction. The angle of the axis is 90°, engagement angle is 20°. Various bevel gear combinations are available from norelem. In most cases the driven bevel gear is smaller than the driving bevel gear however, this is dependent on the respective bevel gear ratio (1:1; 1:2; 1:3; 1:4).

The bevel gears from norelem are pre-bored with a keyway. The toothing is milled. Bevel gears from norelem are very high quality and reliable.