Pneumatic cylinders from norelem

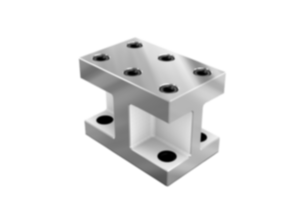

The norelem pneumatic cylinders carry out a rectilinear movement using compressed air. Pneumatic cylinders are also sometimes (but rarely) called compressed air cylinders. The pneumatic cylinders can be operated with filtered dry air or lubricated air and unlubricated air. They are suitable for ambient conditions with a temperature range of -20 °C to +80 °C.

Due to the robust design, these pneumatic cylinders can be used for diverse applications in many different sectors. Examples of applications for pneumatic cylinders are Injection moulding tools, conveyor, drive or handling technology.

Construction & function of pneumatic cylinders

The materials used in the entire range of pneumatic cylinders from norelem are aluminium or stainless steel for the cylinder tube, aluminium or die-cast aluminium for the end cap, stainless steel or high-carbon steel for the piston rod and polyurethane or acrylonitrile butadiene rubber for the piston and piston rod seals. The cylinder pistons are made of brass, the piston guide bush of sintered bronze.

The cylinder tubes are supplied anodised or bright, the end caps bright, painted or anodised, the piston rods bright or hard chromed (depending on model).

Pneumatic cylinder designs

In the norelem online shop, pneumatic cylinders are offered in three different designs Pneumatic standard cylinder, Pneumatic compact cylinder and Pneumatic round cylinder.

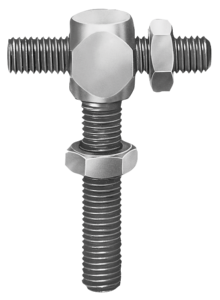

Pneumatic standard cylinders DIN ISO 15552

The DIN ISO 15552 light design standard cylinder is available with a piston diameter of 32 to 80 mm and stroke lengths of 25 to 250 mm. Due to its optimised design, 20 percent of the material can be saved during production of this standard cylinder. The cylinder tube is made of anodised aluminium, the piston rod of hard chromed, high-carbon steel. The piston rod with male thread has adjustable pneumatic damping and can be supplemented with position sensors.

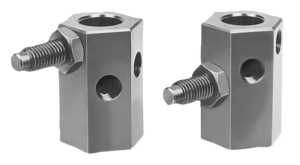

DIN ISO 21287 double acting pneumatic compact cylindes with magnetic piston

The DIN ISO 21287 compact cylinders from norelem can be supplied with male or female thread, piston diameters of 20 to 40 mm and stroke lengths of 10 to 50 mm. The DIN ISO 21287 compact cylinders are equipped with elastic damping on both ends and can be supplemented with position detection for proximity switches. The cylinder tube is made of anodised aluminium, the piston rod of stainless steel. The compact cylinder is particularly suitable for use in confined installation spaces. The pressure applied to the pneumatic cylinder responds promptly.

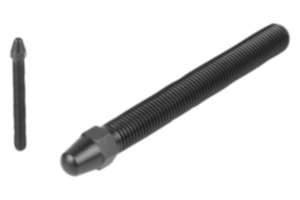

DIN ISO 6432 pneumatic round cylinders

As by the compact cylinder, the DIN ISO 6432 round cylinder from norelem also has elastic damping on both ends and can be suplemented with positioning sensing for proximity switches. The round cylinder has piston diameters of 10 to 25 mm and stroke lengths of 10 to 200 mm, the material is stainless steel. The round cylinder is also characterised by standardised precision fit. Pneumatic round cylinders are ideal for applications with lighter loads or forces and can also be installed without fastening elements.

Single acting vs. Double acting cylinders

In the norelem online shop and THE BIG GREEN BOOK a distinction is made between pneumatic cylinders with single acting and double acting cylinders.

Single-acting pneumatic cylinder | Double-acting cylinder |

Has only one air port | Is operated purely with compressed air |

Requires a spring to return to the start position | The pneumatic cylinder is moved out and in with compressed air |

When retracting and advancing, the pneumatic cylinder can work at almost full power |

Advantages of pneumatic cylinders

- Infinite switching between or regulation of the cylinder speeds and forces

- Achievement of enormously high working speeds

- In the event of overload up to stoppage, compressed air devices usually have the advantage of remaining undamaged

- Compared to electrical appliances, compressed air appliances are of simple design; therefore, generally lighter

- In contrast to electrical systems, in pneumatic systems the waste heat does not occur in the decentralised electric drive units but, without exception centrally, in the compressor itself

- Pneumatic systems do not require return lines as any exhaust air produced can escape directly into the environment