Fixture clamps, fixture clamp screws

Fixture clamps and cam screws from norelem

High repeat accuracy thanks to fixture clamps

Cam screws and their importance in industry

Quick and effortless clamping of components with our innovative tools

More than just fixture clamp – our range with stop and clamping elements

norelem as a reliable partner for fixture clamps

Fixture clamps and cam screws from norelem

Fixture clamps and fixture clamp screws are standardised parts that belong to the group of clamping elements. Clamping elements are used to fasten or clamp components or workpieces in a fixed position. Clamping elements are used in various industrial applications, particularly in manufacturing, machine tools, assembly processes and woodworking. Their main purpose is to ensure stability during the machining process and to improve the precision of operations.

Would you like to view the CAD data of a product before purchasing it? Create a customer account now and get access to all CAD data!

High repeat accuracy thanks to fixture clamps

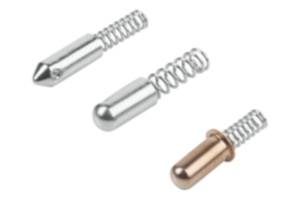

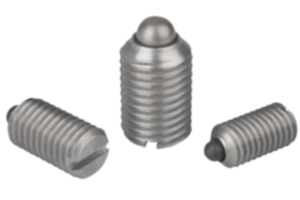

Fixture clamps are tools that are used in the machining of workpieces to enable precise alignment and fixating of parts. They usually consist of a rotating locating pin that is screwed into the workbench. Fixture clamps are used in various areas of industry wherever workpiece clamping is required, be it in metalworking or woodworking.

They are used by screwing the locating pin into the workbench to ensure precise positioning. The cams enable efficient fixating of the parts to be machined during the machining process. This leads to precise and high-quality results.

The importance of fixture clamps in industry, especially in woodworking, lies in their ability for precision centring. Some key aspects of their importance are given below:

- Precise alignment: The cams enable extremely accurate alignment of parts. This is crucial for the quality of constructions, especially complex joints.

- Repeat accuracy: By using high-quality materials such as stainless steel, case-hardening steel, brass and steel, fixture clamps offer high repeat accuracy. This is particularly important in series production where many identical parts are manufactured.

- Efficient fixating of components: The tools enable efficient fixating of parts, which is essential during the machining process. Secure fixation minimises the risk of displacement and irregularities.

- Wide range of products and applications: In addition to fixture clamps, our product range also includes fixture clamp screws as well as stop and clamping elements. The variety extends the range of applications in various machining scenarios.

Overall, fixture clamps help to improve work processes in workpiece clamping technology, enhance the quality of constructions and increase efficiency in the manufacture of products.

Cam screws and their importance in industry

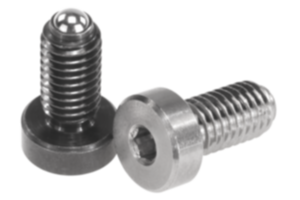

Fixture clamp screws are special screws used in conjunction with fixture clamps in workpiece clamping technology. They can solve a variety of clamping problems, especially in fixture and equipment construction. Fixture clamp screws ensure secure fixation, which reduces the risk of displacement and irregularities. Each cam screw has its own advantages.

A cam screw with knife edge washer is suitable for clamping blanks such as cut stock or cast and forged parts. The screw itself is made of Q&T steel, while the claw disc is made of case-hardening steel.

In the the fixture clamp screw with hexagon washer , the brass clamp nut provides gentle but firm and secure clamping of workpieces. Entire machine pallets can be set up by using several fixture clamp screws.

The versatility of fixture clamp screws lies in their different versions and the fact that they can be used in various applications.

Quick and effortless clamping of components with our innovative tools

Fixture clamps offer various advantages that help to achieve precise and high-quality results. One significant advantage is that fixture clamps enable extremely precise alignment of parts. The rotating locating pin allows workpieces to be centred and positioned precisely. The exact alignment of the parts results in very high repeat accuracy. The use of high-quality materials such as steel, case-hardening steel, stainless steel and brass also ensures a high level of repeat accuracy.

norelem offers many different product variations. The range includes not only fixture clamps and fixture clamp screws, but also other stop and clamping elements.

The clamping elements also boast the following features:

- Compact design

- Quick and easy clamping of components

- A tension lever on some products. This enables tool-free clamping

More than just fixture clamp – our range with stop and clamping elements

In addition to the classic fixture clamps and fixture clamp screws, the range includes the following products:

- Stop: Matches the talon grip and is made of steel.

- Stop element: Using two stop elements and fixture clamp screws with square washer and riser, it is possible to build a cost-effective clamping fixture.

- Cam screw: Can be used as a replacement screw for the fixture clamps or fixture clamp screws. The screw is made of Q&T steel and is available in two forms.

- Machinable fixture clamps: Have a disc whose contour can be adapted to the workpiece to be clamped by milling. This adaptation enables positive clamping, especially for round, contoured or fragile workpieces.

- Chock clamp: Has a space-saving design and a pull-down effect. Due to the lateral clamping, the clamp has no protruding edges.

- Cam clamp: Made from brass. The cam clamp is used to fasten components in plates and workpieces. This clamp can be used to connect components to each other, whereby the connection can be undone if necessary.

- Clamping plate: Made from stainless steel. It is used in combination with fixture clamps and minimises scratches on the workpiece.

- Talon grip: Talon grips are intended for installation in clamping jaws. A slot with tapped holes is sufficient for installation in a vice.

- Spiral cam screw: Is stable and compact. The cam screw enables clamping with a positive down force on various workpiece shapes.

The wide range of clamping elements enables us to offer you a variety of solutions and meet the many different requirements of the manufacturing industry.

norelem as a reliable supplier of fixture clamps

norelem offers a wide range of fixture clamps of the highest quality that fulfil the most diverse requirements in workpiece clamping technology. Our comprehensive range enables customers to select exactly the tools that meet their specific needs. The fixture clamps available are manufactured from high-quality materials such as stainless steel, case-hardening steel, steel and brass. This ensures not only high durability, but also precise and reliable performance.

We attach great importance to customer satisfaction. Our team is on hand to help you choose the right fixture clamp and answer any questions you might have. Order your fixture clamp from norelem today and make the most of our fast delivery. Do you have any questions or need additional information?