wedge clamps

Wedge clamps by norelem - maximum safety and stability

Versatile application possibilities of wedge clamps

Sturdy design for long-term performance of wedge clamps

Time and cost savings through the wedge clamp by norelem

Wedge clamps by norelem - maximum safety and stability

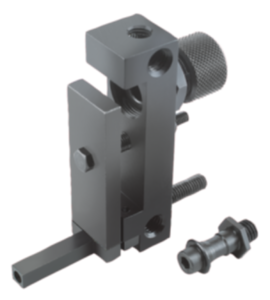

A wedge clamp is used to securely and precisely fasten workpieces. It is part of the clamping tool category and works according to the wedge principle. The clamp consists of a wedge that is inserted between two surfaces and tightened by a mechanism such as a screw or lever. This generates a strong clamping force that holds the workpiece firmly.

Our clamps are characterised by their compact design, which allows for clamping several workpieces in confined space. This feature is particularly valuable for applications, such as in metal and woodworking, where space is limited. Thanks to the sophisticated design our wedge clamps are easy to use and can be quickly adjusted to different workpiece sizes. That saves time and increases efficiency of your operations.

Wedge clamps by norelem ensure maximum safety and stability when fastening workpieces. Our products are made of high-quality materials and designed for durability and reliability.

Due to their versatility, sturdiness and easy handling, wedge clamps are widely used in many sector of industry and craft.

Versatile application possibilities of wedge clamps

Wedge clamps are crucial tools in many industrial sectors. If serial production, assembly of complex components or processing of delicate components – the clamps provide the necessary stability.

Below you can find some examples of how wedge clamps are used.

- Metal working: Our wedge clamps provide secure fastening for precise machining such as milling, drilling and grinding of metal workpieces. The compact design allows several workpieces to be clamped at the same time, which increases efficiency in serial production.

- Wood working: The clamps firmly fasten pieces of wood during sawing, planing or milling. The option of clamping several workpieces at once streamlines the workflow and increases productivity. In addition, accuracy and repeatability are increased, as a result reducing the number of rejects.

- Machine construction: The clamps are sturdy enough to securely fasten heavy and complex components. They can be attached to different machines and devices, which increases their range of applications and offers flexibility. The high load rating and flexibility of our wedge clamps make them important tools in machine construction.

- Electronics production: For the production of electronic components, wedge clamps provide the necessary precision and dimensional accuracy. The clamps hold and fasten small and delicate parts securely. They ensure precise positioning of components, which is crucial for the functionality of electronic devices.

Wedge clamps by norelem are essential in many industries due to their versatility. Whether it's in areas already mentioned, the automotive industry or in specialised areas such as medical technology – wedge clamps provide the necessary stability and efficiency to meet your requirements.

Sturdy design for long-term performance of wedge clamps

These clamping elements are available in different materials. Depending on your requirements, clamps can be selected made of aluminum, case-hardening steel, steel, QT steel or tool steel. The maximum clamping force ranges from 2 kN to 60 kN. The size of thread can also be selected – norelem wedge clamps range from M4 to M16..

Besides standard wedge clamps made of QT steel or made of aluminum profiles and stainless steel the range also includes other types of clamping elements.

Below, we will look at the individual wedge clamps in more detail.

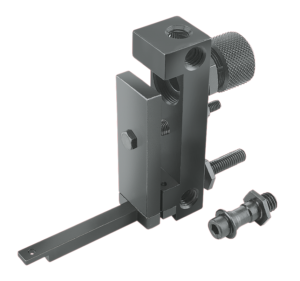

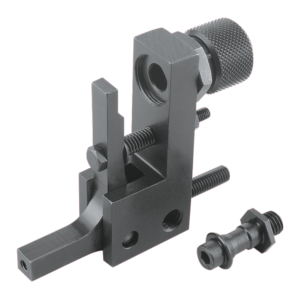

Wedge clamps with fixed jaw

Clamps with fixes jaw are ideally suited for the multiple clamping process due to their unique operating principle. The particular wedge surfaces can create large clamping forces, which ensure that workpieces are fastened securely and firmly.

In order to use a wedge clamp, it is inserted into a T-slot. When the clamping screw is turned, the clamping segment moves outwards and presses the workpiece against the fixed stop jaws of the machining fixture.

Thanks to the integrated slot in the double wedge, wedge clamps can be moved to compensate for tolerances and allow for precise positioning..

Double wedge and clamping segment are made of case-hardened steel, hardened and phosphated.

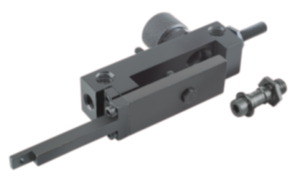

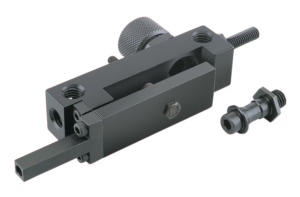

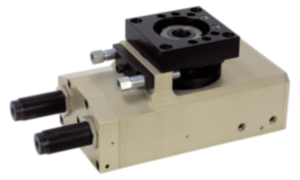

Wedge clamp with machining allowance

Clamps with machining allowance allow clamping of two workpieces at the same time. This significantly increases efficiency and productivity in manufacturing.

The clamping elements are designed so that the workpieces can interlocking and therefore absolutely securely be clamped in due to the corresponding milling grooves. Their compact design allows for space-saving multiple clamping process, which is particularly advantageous in production environments with limited space.

The wedge of the clamp is made of case-hardened steel and the outer part of an aluminum profile.

Tensioning force can be selected as follows:

- 2,2 kN

- 6,7 kN

- 8,9 kN

- 15,6 kN

- 26,7 kN

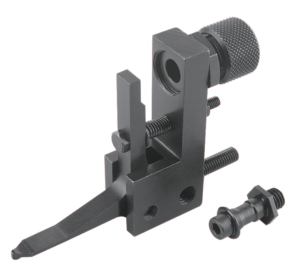

Wedge clamp with smooth or serrated clamping surface

Wedge clamps with a smooth surface have an even, smooth surface that comes into direct contact with the workpiece. This smooth surface reduces the risk of damage or marks on the workpiece, making it perfect for delicate surfaces or workpieces that require a flawless finish. Thanks to gentle clamping, they can be used universally and are particularly suitable for processing high-quality materials where any surface changes must be avoided.

In contrast, wedge clamps with serrated surface provides a structured surface for additional grip. This serrated structure grips the workpiece more firmly and prevents slippage, even under high clamping forces. They are particularly useful for machining heavy or large workpieces that require maximum stability and safety. Serrated clamping surfaces ensures that workpieces remains steady even during intensive machining operations, which increases precision and efficiency of the work.

Due to these different clamping surfaces, wedge clamps can be used in a number of possible applications and be selected according to the requirements and type of workpiece. The decision for a smooth or serrated clamping surface depends on the specific application.

Time and cost savings through the wedge clamp by norelem

Wedge clamps by norelem offer considerable advantages in terms of time and cost savings, making them a valuable investment for any production environment.

The clever design allows for quick and uncomplicated clamping processes. This significantly reduces setup times and allows users to spend more time actually machining the workpieces. Simple operation and quick adjustment to workpiece of different sizes also contribute to efficiency.

The high precision and stability of norelem clamps minimize material wear and the risk of damage to workpieces. This results in a longer service life for the machined parts and fewer rejects, which in turn reduces material costs.

Wedge clamps by norelem are not only tools for fastening workpieces, but an investment in the efficiency and profitability of your production. They greatly reduce setup times, require less space, minimize material wear and are low maintenance and, as a result, contributing to substantial savings in terms of time and costs. You can rely quality and reliability by norelem to streamline your production processes and reduce operating costs.