Stops

Stops

Stops are used on fixtures and machine tools for positioning workpieces and components. They can also used to adjust and position plate workpieces. Many different stops, from simple adjustable stops with screws, or eccentric stops to complicated 5D workpiece stops can be found in the norelem range.

Precise and reliable - workpiece stops by norelem

What is a workpiece stop?

Wide-ranging solutions for your requirements – our product range of workpiece stops

Workpiece stops by norelem

Precise and reliable - workpiece stops by norelem

Workpiece stops are operating parts that ensure precise positioning and fastening of workpieces. During the machining process they hold workpieces exactly where they need to be, which increases accuracy and consistency of the work.

Operating parts are primarily used in metal and wood processing. Precise positioning is particularly important in serial production. In this case even the slightest deviation are not acceptable. A workpiece stop prevents errors and saves time. It is available in many different styles and sizes.

There are various styles of workpiece stops to suit different machines and machining requirements. They can be adjusted to different machines and workpieces. The right choice of workpiece stop improves work processes and increases productivity.

In summary, stops are very important in any industrial application that requires high precision and repeatability. By using workpiece stops, companies are able to increase efficiency, improve quality and reduce costs by minimising errors and waste.

What is a workpiece stop?

Workpiece stops are operating parts that ensure that each workpiece remains in exactly the same position during processing. The way a workpiece stop works is based on the precise positioning and fastening of workpieces. To ensure consistent machining, you should proceed clamping as follows:

Positioning: The workpiece is positioned against the workpiece stop. Depending on the machine and the application this can be done manually or automatically. The stop ensures that workpieces remain in the desired position.

Fastening: Once the workpiece is correctly positioned, it is fastened in place. In case of screw stops, this is done by tightening the screws. Magnetic stops use the magnetic power to hold workpieces securely. In some cases, additional clamps or tensioning devices are used to reinforce fastening.

Processing: The machining process begins as soon as the workpiece is securely clamped in position. The workpiece stop ensures that the workpieces do not slip or move during machining, which improves precision and repeatability of machining.

Release: After the machining process is complete, workpieces ares released. For screw stops, screws are loosened; for magnetic stops, the magnetic fastening is removed.

Stops by norelem are made of different materials. The materials used in the manufacturing process are aluminum, steel and QT steel. Each of these materials has unique advantages in terms of durability, sturdiness and other properties.

Aluminum, for example, is significantly lighter than steel, which makes handling and installing stops easier. Steel, on the other hand, offers high mechanical strength and is resistant to deformation and breakage. Above all, steel withstands repeated stress and vibration well, making it ideal for dynamic applications. QT steel is also part of this. It is extremely resistant to wear and mechanical stress and can withstand high static and dynamic loads.

Aluminum dissipates heat well, which reduces the risk of overheating during certain machining processes. In addition, the material forms a natural oxide layer that protects it from corrosion, which is particularly advantageous in humid or chemically aggressive environments.

Wide-ranging solutions for your requirements – our product range of workpiece stops

There are different types of workpiece stops. Which workpiece stop may be suitable for your application depends on your requirements. It is therefore important to have a good knowledge of the workpieces.

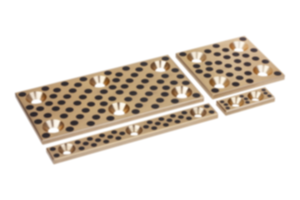

In addition to the various stops, the range includes accessories such as:

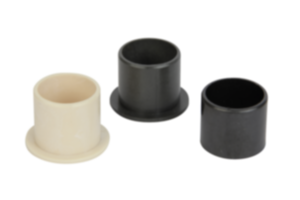

adjustable stops

Adjustable stops can be adjusted to accommodate different workpiece sizes and shapes. They are versatile and offer flexibility in a range of machining processes. Adjustable workpiece stops by norelem features three threaded holes for holding set screws. Body and set screw are made of QT steel. Body and set screw are black oxidized, the adjusting screw is tempered as well.

Clamping stop

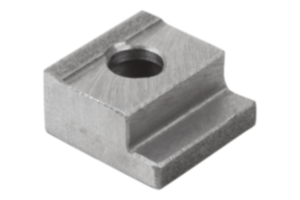

This special workpiece stop is designed for use with slot profile systems. It offers the flexibility to be moved along the slot profiles and be fastened in the desired position. This allows for precise and repeatable positioning of workpieces. Clamping stops for slot profiles are perfect for modular setups and can easily be adjusted to meet different processing requirements. They are particularly useful in applications where quick and frequent changeovers are required.

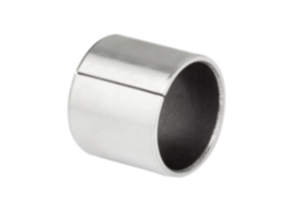

Screw stops

Screw stops use screw mechanisms to fasten workpieces. They can be precisely adjusted and provide very steady fastening, which is particularly important when high machining forces are applied. Screw stops by norelem are made of QT steel. The operating part is tempered and black oxidized.

5D-swivelling stop

5D-swivelling stop

5D-swivelling stops control the position of workpieces in five dimensions: three linear axes (X, Y, Z) and two rotating axes. They offer the highest precision and are used in applications that require very complex machining operations, such as in the aerospace industry. 5D-swivelling stops feature a clamping joint made of high-strength aluminum – their hinge pin, support plate and stop rod are made of steel.

Magnetic Stops

Workpiece stop with enclosed magnet includes a strong magnet for fastening metal workpieces in place. It adheres to any magnetic surface, such as vices, measuring devices, drilling and milling machines. After workpieces have been fastened, the workpiece stop can simply be removed, making all machining surfaces accessible again. Magnetic workpiece stops are easy to install and remove and are ideal for quickly changing workpieces.

Eccentric stops

Eccentric stops are characterised by their eccentric winding mechanism. A bolt that is not centered but offset allows for fine adjustment of the stop by turning. These stops provide precise fastening and are perfect for applications that require flexible and exact positioning. They combine high clamping force with ease of use and are particularly useful for machining small or delicate workpieces. Eccentric stops by norelem are made of QT steel, tempered and black oxidized. It is available in different sizes with different diameter.

Workpiece stops by norelem

norelem is one of the leading supplier of standard parts and components for machine and plant construction industries. Our workpiece stops are characterised by the highest precision, durability and a wide range of customisation options.

norelem customers of workpiece stop not only benefit from our many years of experience but also our comprehensive know-how. Our products are made of high-quality materials such as aluminium, steel and QT steel, which guarantees sturdy and reliable use. We also offer a wide range of stop types ranging from adjustable stops and screw stops to high-precision 5D-swivelling stops as well as eccentric stops.

Our team is there to help you choose the right components and answer any questions you may have about their application. Trust in KIPP - Quality and know-how at its best.