Slide guides

Carriage guides from norelem enable vertical and horizontal positioning and movement. The carriage guides can be flexibly adapted to different requirements and are therefore the ideal choice for a wide range of applications in machine and fixture construction such as measuring and control technology.

Application fields of carriage guides

Due to their high precision, carriage guides are very popular in the fine mechanics industry, for applications in machine, fixture and measuring instrument and optical construction. For example, the micrometer spindle can be used to precisely adjust products and secure them in a desired position.

Materials used for carriage guides

Grey cast iron and aluminium are used as materials for the carriage guides, with the aluminium versions representing an excellent compromise between weight, load capacity and precision. Optionally the carriage guides are available with end stops and micrometer spindles.

A carriage guide from norelem has the following advantages:

- Long service life

- Quick combination of several axis systems

- Highest precision

- Good vibration absorption

- Low maintenance

- Resilient, robust construction

- Play-free guides

- Innovative and secure clamps

Carriage guide models

2 carriage guide product groups can be found in ""THE BIG GREEN BOOK"" and the online shop. The dovetail slides and the precision slides.

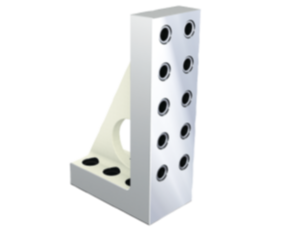

Dovetail slides

The dovetail slides which operate on the slide guide principle are highly resilient. The large contact surface area of the dovetail slides permit very high permissible loads of up to 1500 N.

The dovetail slides are available in widths of 20 to 150 mm and lengths of 30 to 310 mm. The individual clearance between the inner and outer guide is adjusted using a tapered bar. All outer surfaces are ground and the guides are precision milled. Models equipped with a threaded spindle have a knob with 0.02 mm scale divisions for travel adjustment.

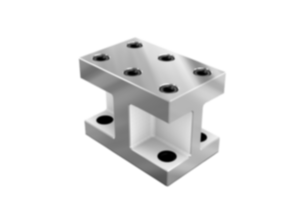

Precision slides

Roller mounted precision slides made of cast iron convince by thier smooth operation and high precision. They are available in widths of 40 to 100 mm and lengths of 50 to 360 mm.

The roller mounted carriage guides have hardened and ground cross-roller slides. These guarantee smooth and backlash-free running as well as minimal initial friction, so that only low motive forces are required.

Dovetail slides vs. precision slides

The general difference between a dovetail slide and a precision slide is the guidance method. The dovetail slide has a slide guide which looks like a doves tail when viewed end on, and has a higher load capacity. The precision slides on the other hand, have roller guides, making them more precise.

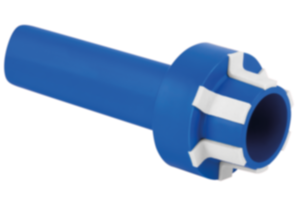

Dovetail slides and roller mounted precision slides can be each be assembled to form cross tables using the fastening screws for cross table mounting. This is a further advantage of the new generation of carriage guides: There is an additional centring hole on all tapped holes. In conjunction with the appropriate centring rings, several carriage guides and other connecting elements can be precisely mounted on the slide.

Accessories for carriage guides

In the norelem range of carriage guides can be found accesories such as guide rails with cross rollers, roller cages for guide rails, teflon-coated guide rails, mounting brackets, straps and fastening screws for cross table mounting.

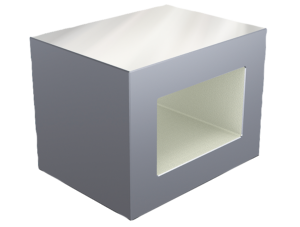

Straps

The straps are used to clamp the carriage guides in the X, Y and Z axis and to fasten the guide unit to the machine. Travel is reduced when used on the end face.

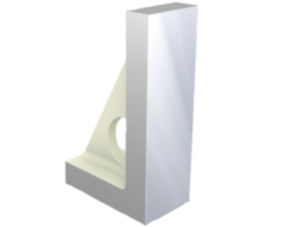

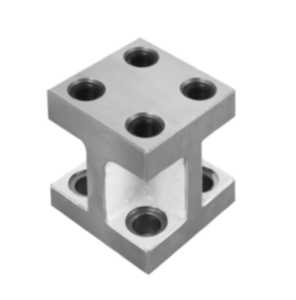

Mounting brackets

With the mounting bracket two carriage guides can be connected to an X-Y configuration without reducing travel. In connection with our centring ring 20240 the vertical slide can be centered precisely on the horizontal slide and fastened using DIN 912 screws (07160).