Linear glide guides

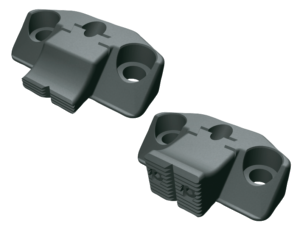

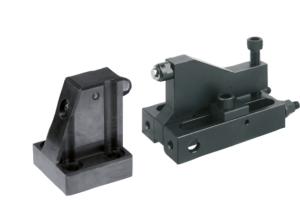

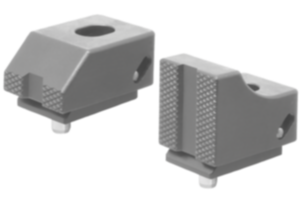

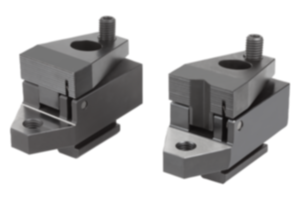

DryLin® linear glide guides (plastic slide guides) execute linear movements without the use of lubricants. The dry-running linear guides are resistant to dirt and glide without oils, greases or lubricants. The products from norelem are maintenance-free, adjustable, quiet and corrosion resistant.

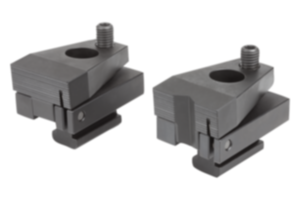

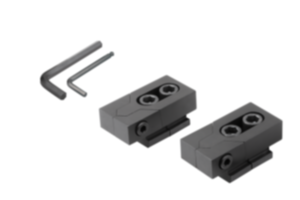

Technical data for DryLin saddle slides

Eccentric forces

Some recommendations must be followed in order to use the maintenance-free DryLin linear bearings effectively. Because the friction is higher compared to ball guides, a greater force must be applied. The largest possible bearing spacing along a rail and the lowest possible moment loads from the drive and mass have a positive effect on the operating and wear characteristics of the guide.

Quiet running

Plastic bearings, which run on ground shafts or profiled rails, hardly cause any noise. Contrary to conventional ball-bearing guides, the noise level does not increase as the speed increases.

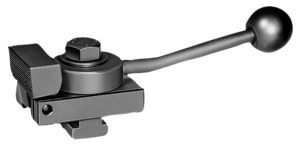

The 2:1 Rule

If the 2:1 rule is not respected when using linear slide bearings, this will result in an uneven course of movement or even in the system becoming jammed. This can often be remedied by making relatively simple changes. The principle does not depend on load or force; it is a product of friction and always relates to the fixed bearing.

The further away the drive is from the guide bearing, the greater the wear and required force become. If the distance from the driving force to the fixed bearing is more than double the bearing spacing (2:1 rule), the guide would theoretically jam at a static friction of 0.25.

Design notes:

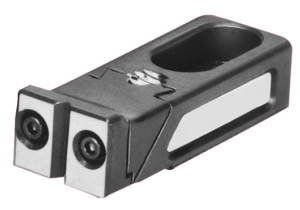

When using systems with two parallel rails, one end must be designed as a floating bearing. For each mounting position (horizontal, vertical or lateral) there is an appropriate fixed/floating bearing solution. This installation concept prevents difficult movement or jamming of the guide in case of the rails deviating from parallel.

The floating bearing is implemented by removing the hyperstatic slide elements. This allows a further level of freedom along the rail in the direction of the predicted parallelism fault. Compensating for parallelism faults between the mounted rails is possible in a fixed/floating bearing up to a maximum of 0.5 mm. During installation, you must make sure the floating bearing exhibits approximately the same degree of play in both directions. The recommended configuration of the fixed/floating bearing system can be seen in the accompanying illustrations.

The connecting areas for the rails and guide carriages should be sufficiently even (e.g. ground surface) in order to avoid tension in the system. Slight unevenness on the connecting areas can be compensated for individually up to a specified dimension (0.5 mm) by increasing the play. Play adjustment is only effective when no loads are applied.