Positioning systems

The comprehensive norelem product range includes a wide selection of positioning systems. Alongside the motorised positioning stages, norelem also has classic manual positioning systems.

Exact positioning in tooling or handling systems is easily facilitated due to the virtually backlash-free guideway of the positioning stages. The slide can be adjusted without having to lock or loosen the spindle, thanks to the spindle being backlash-free. The radial play in the slide is less than 0.02 mm. Another big plus of the positioning stages is that the spindle is self-locking with an additional clamping function.

Application areas for positioning systems

The norelem positioning systems can be used in machine and special machine construction, metrology, optical applications, many automation sectors, laboratories for creating test fixtures and model fabrication.

Positioning system materials

The bearing blocks and slides of norelem positioning stages are made of an aluminium alloy, which is then anodised. The guide columns and rolled thread spindles are produced from stainless steel. The slide is also fitted with a maintenance-free plain bearing in order to move it with as little resistance as possible. Plastic position indicators are offered in the online shop depending on the type of positioning stage.

Advantages of positioning systems

- Visible scale (the spindle travel can be read to an accuracy of 0.1 mm)

- Self-locking

- Clamping function

- Backlash-free guidance of the positioning systems

- Modular positioning systems: Due to the practical modular principle, the positioning stages and rotary stages from norelem can be arbitrarily combined with the respective cross tables or vertical stages of the same size.

- Maintenance-free plain bearing guides in the positioning system

- Longer product life cycle without strenuous maintenance work on positioning stages

Types of norelem positioning systems

In addition to conventional positioning stages, norelem offers technicians and designers positioning stages with integrated position indicators as an additional option. These indicate the position of the slide by means of a display with an accuracy of 0.1 mm. A position indicator can be attached to four different locations on the slide using a screw connection.

For automated applications, the positioning stages are also available with electric drive and integrated control.

The positioning systems can be ordered in short and long versions, as positioning stages, cross tables, vertical stages or rotary stages.In addition, the norelem online shop/product catalogue offers a full range of matching accessories for the positioning systems, such as vertical brackets, rotary discs, swivel angles, rod ends, baseplates and angle plates for the positioning stages.

Positioning system travel

The travel range of the positioning systems varies depending on the length of the positioning stage:

- Between 11 mm and 25 mm by the short stages

- Between 23 mm and 86 mm by the long stages

Positioning stages and cross tables can be adjusted right and left, vertical stages up and down.

Positioning systems

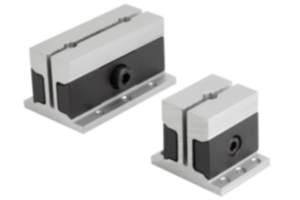

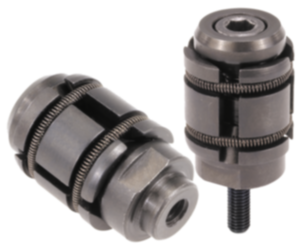

Positioning stages

The norelem positioning stages are available in 6 versions: As short models without position indicators, with position indicators or with electronic position indicators. The long versions of positioning stages are also avaialble without position indicators, with position indicators or with electronic position indicators from the norelem product range.

Cross tables

Cross tables differ from positioning stages by the expansion with accessories. Cross tables can be easily supplemented with vertical stages and other accessories.

Vertical stages

Vertical stages are used when components and assemblies (e.g. stops, sensors, limit switches, tables, cameras, entire assemblies, etc.) need to be positioned at a certain height.

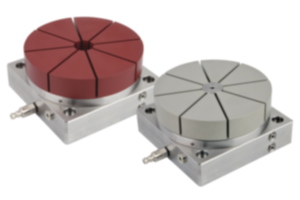

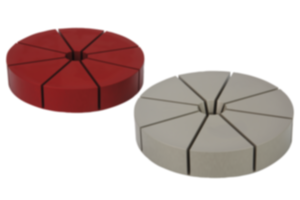

Rotary stages

Rotary stages from norelem can be moved through a 360° with end stops.

The comprehensive range of positioning systems also includes vertical brackets in short and long versions, rotary discs, swivel angles, pivot head rod ends, baseplates and angle plates.