High permissible load for maximum stability – Levelling feet from norelem

Types of levelling foot

Advantages of levelling and machine feet

Selecting the correct levelling foot

Levelling feet from norelem

High permissible load for maximum stability – Levelling feet from norelem

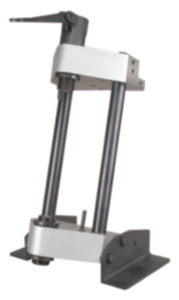

Machine feet and levelling feet are essential components that are used in many areas of industrial production. They are called levelling feet for a reason. Although they are often overlooked, they play a crucial role in the stability, safety and functionality of machines and equipment.

Machine feet are specially developed support components that are mounted under machines and systems. They are used to hold the machine stable on the floor, dampen vibrations and precisely align the machine. This is particularly important in industrial settings where precise and safe working conditions must be guaranteed.

Levelling feet, on the other hand, are often found on furniture and smaller appliances. They enable height adjustment and alignment on uneven floors to prevent tilting or wobbling. Their adaptability contributes to creating an even and stable platform, which not only improves aesthetics, but also increases functionality and safety.

With levelling feet from norelem, machines and many other installations for industry, laboratories, medical and biotechnology are ideally placed. The feet impress through:

- their stable and robust construction

- the possibility of rapid installation

- their high-quality finish

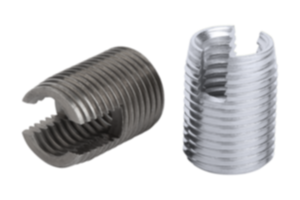

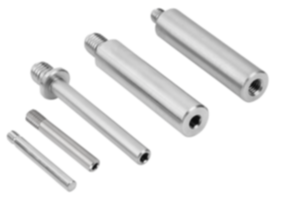

Our levelling feet consist of two components - a threaded spindle and a plate. These two components have the major advantage that any threaded spindle can be combined with any plate. It is particularly important that the threaded spindle is firmly joined to the plate after being pressed in.

Thanks to this combination option, the machine feet can be customised to suit the application. No wonder that the feet are used in machine and plant construction as well as in the furniture industry, e.g. for office tables.

Types of levelling foot

The main tasks of machine and levelling feet are to ensure stability and alignment, dampen vibrations and thus extend the service life of the mounted objects. Particularly in industrial environments where heavy machinery is placed on uneven or vibrating floors, machine feet can make the difference between safe, efficient operation and potential failure or damage.

The norelem range includes 30 different products in this catagory. Using different plates and the various types results in a multitude of combination possibilities. This enables you to create levelling feet for your individual purposes.

Our range is enhanced by accessories such as cup elements, vibration absorbers and caps.

The levelling feet from norelem are predominantly made of metal. They are highly stable and can withstand high loads. The materials used are steel, stainless steel, die-cast zinc and aluminium.

End caps and knurled bases are made from plastic. Anti-slip plates made of elastomer thermoplastic prevent the levelling foot from slipping from the outset.

Levelling feet for machines and many other industrial installations are available in many designs, with a thread or:

A special type to emphasise are the levelling feet in Hygienic DESIGN made from stainless steel. They have a double seal on the thread and a special seal on the spindle joint. These machine feet are particularly suitable for the foodstuff and pharmaceutical industries. Hygienic DESIGN makes the feet easy to clean and inhibits the adhesion of microbes and other contaminants.

Advantages of levelling and machine feet

Machine feet and levelling feet are major components in the construction and placing of machines, equipment and furniture. Although they often remain in the background, they are crucial for the stability, alignment and durability of these objects. Their importance is particularly evident in their numerous advantages.

- High load capacity: Machine feet are specially designed to bear heavy loads, making them ideal for heavy machinery and industrial applications. They provide stable support and prevent large appliances from flexing or wobbling.

- Simple and quick installation: The simple installation of levelling and machine feet reduces both time and labour costs. The uncomplicated installation enables rapid commissioning and minimises downtimes. The use of standard parts facilitates the replacement of worn components. This means that spare parts can be procured more quickly and replaced more easily.

- Versatile adaptability: Levelling feet are available in a variety of sizes, types and materials. This flexibility enables you to select the appropriate feet for different applications and requirements, be it for sensitive equipment or robust industrial machinery.

- Vibration damping: Some levelling feet are fitted with special damping elements to absorb vibrations. This reduces wear on machinery and minimises noise, contributing to a quieter and safer working environment.

- Combinability: Levelling feet and machine feet can often be easily combined with other components such as vibration dampers, mounting shells or fastening elements. This offers additional flexibility in the design and adaptation of machines and systems.

- Easy cleaning and maintenance: Most levelling and machine feet are designed to be easily cleaned and require little maintenance. This helps to maintain hygiene and minimise operating costs.

Our special designs "levelling feet in Hygienic DESIGN" stand out in particular here. These levelling feet are suitable for installations and equipment in medical technology, biotechnology and research and impress with their high quality surface finish. They are also used in the foodstuff industry, beverage manufacturers and in breweries and dairies.

Selecting the correct levelling foot

Selecting the correct levelling feet is crucial for the stability, functionality and durability of machines. Several factors that should be taken into account when making a decision play a key role here.

First of all, the type of machine plays a central roll. Different machines make different demands on the levelling feet, both in terms of size and load capacity. It is therefore important to select levelling feet that are optimally suited to the machine in question.

Another point is the load capacity and permissible load of the levelling feet. The levelling feet must be capable of safely supporting the weight of the machine. It is important to accurately calculate the maximum load on the levelling feet and ensure that the feet selected meet these requirements. Overloading can cause damage not only to the levelling feet themselves, but also to the machine.

The ambient conditions in which the levelling feet are used are also of great importance. In damp or corrosive environments, corrosion-resistant materials such as stainless steel are an advantage. Particularly robust and resistant models are required for extreme temperatures or areas subject to heavy loading.

The material choice is also decisive. Materials such as steel, stainless steel, plastic and rubber have different properties and areas of application. Select the material according to the specific requirements of your application.

Installation and maintenance should also be taken into account. The levelling feet should be easy to mount in order to minimise installation work and the associated costs. It should also be easy to clean and maintain the levelling feet to keep operating costs low and ensure a long service life.

Finally, it is advisable to obtain information about the compatibility of the levelling feet with other components of the system. Good compatibility ensures smooth integration into the existing infrastructure and reduces the risk of problems during operation.

By taking these factors into account, it is possible to ensure that the chosen levelling feet are optimally suited to your requirements.

Levelling feet from norelem

In our online shop you will find a wide selection and numerous variants of levelling feet, suitable for your application and for different environments. In addition to levelling feet and machine feet, we have over 100,000 standard parts and machine components in our range.

We consider ourselves to be an innovative partner and solution provider for technicians, designers and engineers.